PLC and AC70 Vector Inverter Used in Extruder Solution

Aperçu

- Aperçu

- Caractéristiques et avantages

- Produits connexes

- Cas

- Nouvelles et événements

- Solutions

- Contactez-nous

PLC and AC70 Vector Inverter Used in Extruder Solution

Caractéristiques et avantages

Introduction

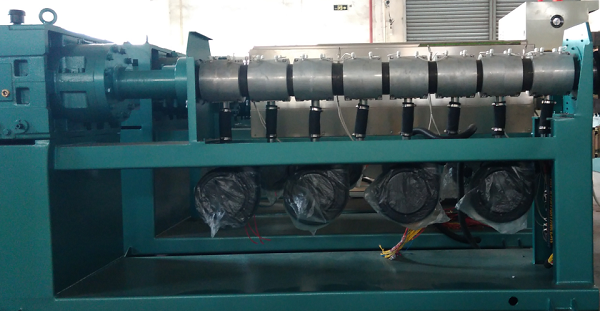

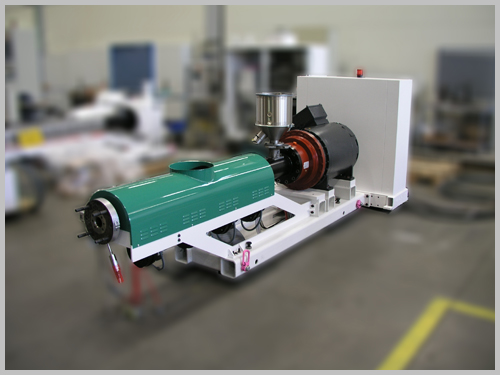

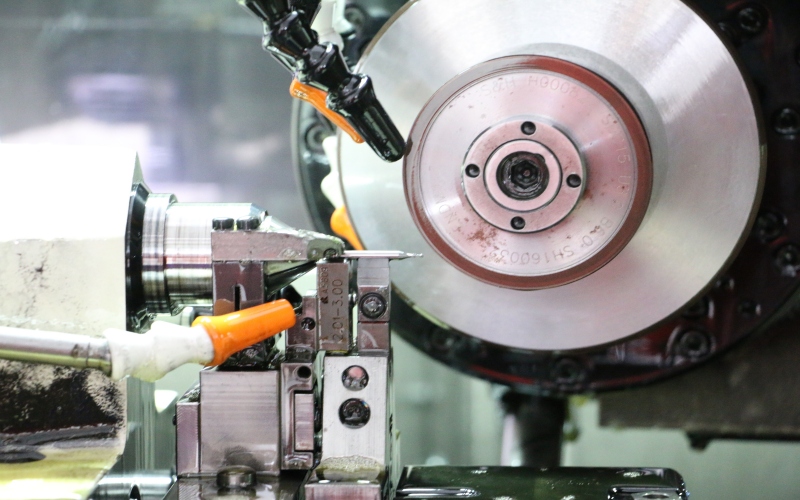

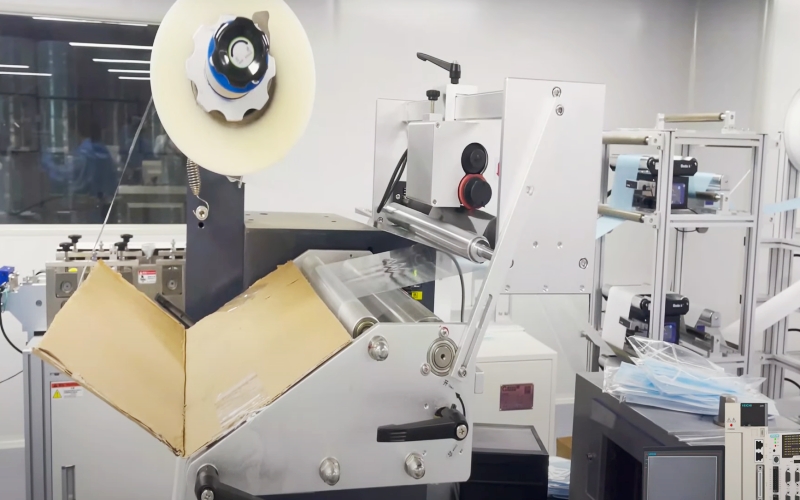

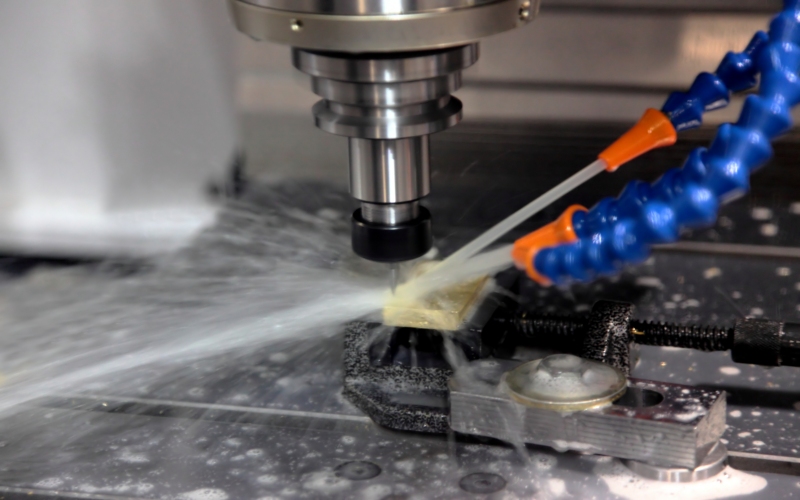

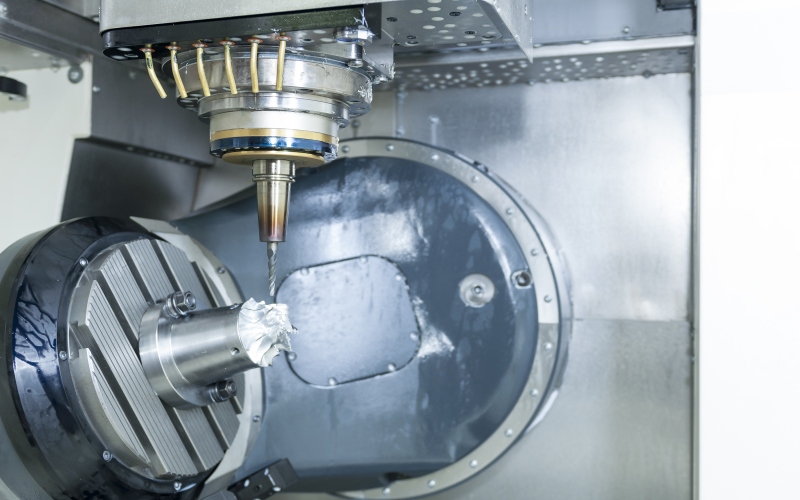

Extruder is widely used in plastic processing machinery. The work process is: the packing machine filling solid material, transportation of solid materials, fused isolation, melt material delivery and final molding. They can be divided into screw extruders and non-screw extruders. This article describes the outstanding performance of Veichi industrial control products on extruders especially screw extruders. Below is the on site pictures.

Disadvantages of Original Control Mode

6-step heating method is taken to meet the processing requirements of heating lights, wires and other products. The temperature increase, constant temperature, temperature overshoot range control and surrounding ancillary equipment requirements are precise in the entire process. The following disadvantages are concluded based on on-site equipment condition and original control mode analysis:

a: The original control mode is not good at temperature control module, with high cost and inflexible control, and temperature control is not satisfactory, mainly as follows: long temperature rising time, large overshoot range, the effect of temperature is also not good.

b: Speed control mode is analog control mode, while the analog module always has resolution accuracy problem, so there will be some errors in geometric control, which would inevitably result in uneven material or other issues when several machines work together.

Veichi Solutions

Main part consists of Veichi VE200 series PLC system and analog input module (the module is specified for the extrusion industry, of which the capture resolution is higher than similar products in the industry) to complete the precise control of the 6-stage heating parts with the accuracy of plus or minus 0-1 degrees;powerful module self-tuning capability makes control more flexible and simple. Geometric synchronous speed drive components using Veichi AC70 series vector inverter and the logic part is completed by VE200 CPU internal powerful floating-point computing while speed error control is less than 0.01HZ; and the given frequency is realized by the complete networking capability of its powerful industrial products without adding additional hardware. VI10 series touch screen is convenient for modifying parameters and monitoring operation status.

Advantages of Veichi System Solution

a. The temperature control smooth operation, without adding other ancillary equipment, flexible temperature control mode, the user may need to choose according to their own processes. Because the rise time, overshoot and other aspects of control is very good, so energy saving and work efficiency are also improved.

b. Precise speed control and small error; the internal communications protocol of Veichi industrial products can complete the geometric control of speed, without adding other elements, and the simple wiring reduces hardware contacts failures.

c. The whole system is composed of Veichi industrial products, which are compatible and stable; technical support and spare parts procurement are very convenient.

Mondial - English

Mondial - English russe - Pусский язык

russe - Pусский язык Chinois - 中文

Chinois - 中文 Coréen - 한국어

Coréen - 한국어 Vietnamien - Tiếng Việt

Vietnamien - Tiếng Việt

Laisser un message

Laisser un message